Modern industrial biscuit production relies on specialized machinery to handle every stage, from ingredient mixing to final packaging, ensuring consistency, food safety, and cost-effectiveness.

Below, we’ll break down the key stages of biscuit production and explain why choosing the right machinery is crucial for success.

1. Dough Mixing: The Foundation of Quality

The first step in biscuit production is to combine the ingredients (flour, sugar, fat, leavening agents, and flavorings) into a homogeneous dough.

Industrial mixers must achieve a uniform consistency without overmixing the dough, which can result in a tough or irregular texture.

Advanced mixers are equipped with programmable controllers that adjust speed and mixing time, ensuring repeatable results from batch to batch.

2. Forming and Shaping: Precision is Crucial

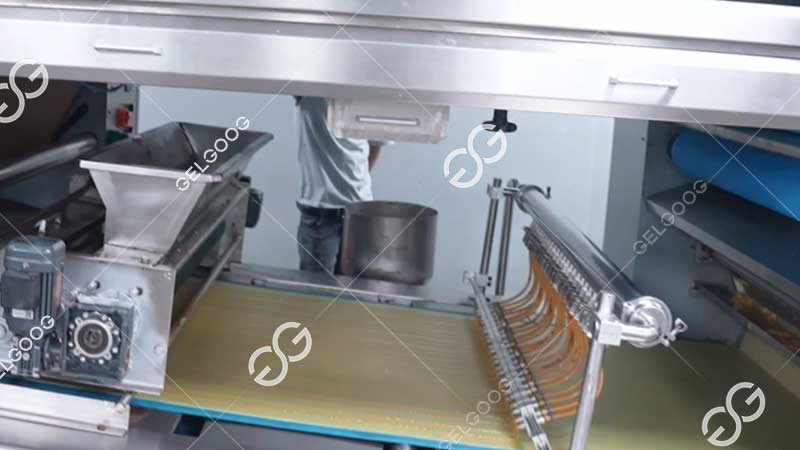

After mixing, the dough is fed into the forming equipment. Depending on the type of cookie, manufacturers use the following equipment:

- Rotary formers for die-cut designs (e.g., shortbread or butter cookies);

- Wire cutters for drop-shaped cookies (e.g., chocolate chip cookies);

- Sheeting and cutting lines for laminated or multi-layered products (e.g., crackers);

3. Baking: The Science Behind Perfect Texture and Color

Baking is the process of transforming dough into finished cookies. Tunnel ovens with multiple temperature zones allow for precise control of the baking profile. Key factors include:

- Temperature profile: Adjusting the temperature at different stages affects the spread, moisture, and browning of the cookies.

- Airflow: Even circulation prevents hot spots and ensures even baking.

- Dwell time: Thicker cookies may need to be baked longer at a lower temperature.

4. Cooling: A critical but often overlooked step

- Freshly baked cookies are fragile and require controlled cooling to prevent cracking or moisture retention. Cooling conveyors equipped with ambient or forced air systems gradually cool the product to room temperature while maintaining a crisp texture.

- Proper cooling also prevents condensation inside the packaging, which can prevent the cookies from spoiling.

5. Packaging: Protection and Display

- The final step is sorting, weighing, and sealing the biscuits for retail or bulk distribution.

- Automated packaging lines increase speed and accuracy while reducing labor costs. Features like metal detectors and checkweighers ensure compliance with food safety regulations.

Why Machine Selection Impacts Your Bottom Line

Investing in the right biscuit production equipment offers tangible benefits:

- Higher yields and fewer defects—Precision machinery reduces waste and rework.

- Lower operating costs—Energy-efficient ovens and automated lines reduce utility and labor costs.

- Scalability—The modular design allows for easy upgrades as demand grows.

- Compliance and safety—The equipment’s hygienic construction complies with global food standards (e.g., FDA, EU).

Looking to upgrade your biscuit production line? Our solutions are designed for maximum efficiency and adaptability. Contact us for a customized consultation tailored to your needs.