Our stick biscuit making machine offers a blend of customizability and operational flexibility. Engineered to adapt to your specific production requirements, it allows for real-time adjustments during the manufacturing process. This ensures you can effortlessly meet varying market demands while maintaining high efficiency and consistent product quality.

Integrated Structure of the Stick Biscuit Production Line

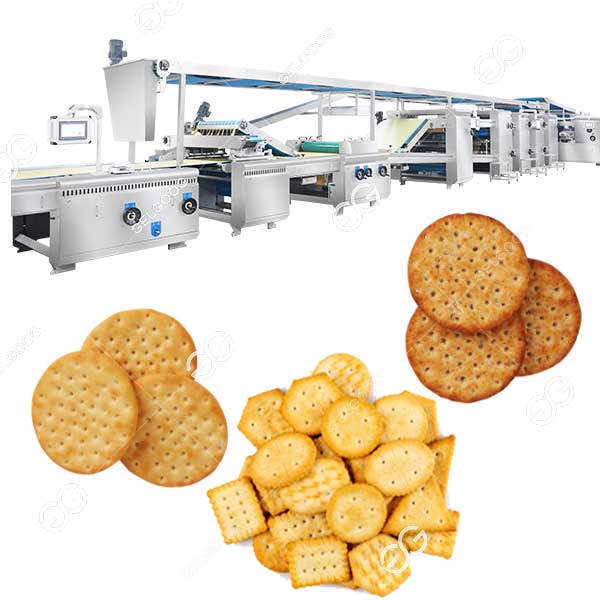

This comprehensive system integrates several key components to automate the entire production process from raw material to packaged product.

-

Automated Raw Material Handling & Conveying

The process begins with raw material silos, precision metering devices, and conveying pipelines. This system stores, accurately measures, and transports ingredients like flour, sugar, and fats to the mixing stage, ensuring perfect recipe adherence every time. -

High-Efficiency Mixing Device

At the heart of the initial processing is a robust mixing unit, comprising a mixing cylinder, specially designed stirring paddles, and a drive motor. The paddle shape and rotation speed can be fine-tuned for different dough recipes, guaranteeing a homogenous and perfectly developed dough.

-

Versatile Forming Device

As a core component, the forming machine shapes the final product. Options include stamping, roller stamping, or rotary cutting formers. These machines precisely determine the shape, size, and pattern of the stick biscuits, with easy mold changes allowing for a wide product range. -

Uniform Baking & Cooling Tunnels

The formed biscuits are baked in a tunnel oven equipped with a heating system, conveyor chain, and precise temperature controls. This setup provides stable, evenly distributed heat for consistent color and texture. Subsequently, a cooling device—using forced air or natural convection—rapidly brings the biscuits to room temperature, locking in crispness. -

Automated Packaging System

The final stage features automatic packaging machines, such as pillow or vertical form-fill-seal machines. These units automatically count, bag, and seal the stick biscuits, readying them for distribution and retail sale.

Key Performance Characteristics & Advantages

-

High Production Efficiency: The fully automated, continuous operation enables outputs ranging from hundreds to thousands of kilograms per hour. This dramatically increases production capacity while significantly reducing labor costs and manual intervention.

-

Consistent & Reliable Quality: Precise control over temperature, speed, and the use of high-quality forming molds ensures every stick biscuit has a uniform shape, consistent size, and identical texture. This guarantees stable, reliable product quality batch after batch.

-

Enhanced Sanitation & Safety: Constructed from food-grade stainless steel, the machine complies with all international hygiene standards. Its smooth surfaces and accessible design simplify cleaning and disinfection, ensuring the highest level of production hygiene and product safety.

-

Remarkable Versatility: Beyond standard stick biscuits, advanced models can produce a diverse range of products. By simply changing molds and adjusting process parameters, you can create different shapes, flavors, and recipes to swiftly respond to evolving market trends.

Essential Maintenance & Servicing Guide

To ensure long-term reliability and optimal performance, a proactive maintenance routine is essential.

-

Daily Upkeep:

-

Thoroughly clean the machine surface after production to remove all dough residues, crumbs, and oil.

-

Perform a visual inspection of key components: check for conveyor belt misalignment, loose chains, and the integrity of heating elements. Address any minor issues immediately.

-

-

Periodic Servicing:

-

Schedule regular comprehensive inspections to replace worn-out parts (e.g., seals, belts).

-

Replenish or replace lubricants in all moving parts as per the manufacturer’s schedule.

-

Calibrate measuring devices and temperature control systems to ensure ongoing precision and energy efficiency.

-

Reviews

There are no reviews yet.