In the healthy snack market, soda crackers are highly favored due to their low fat, low sugar, and high fiber content.

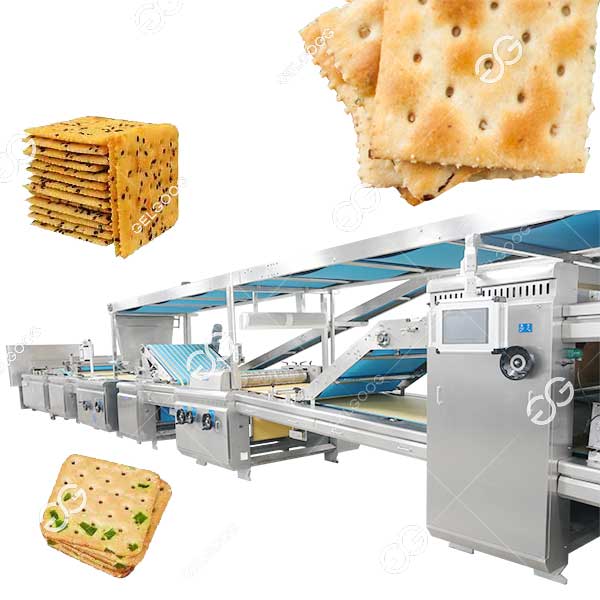

Our fully automatic soda cracker production line, with its core strengths of efficiency, flexibility, and hygiene, has become the perfect solution for food processing companies of all sizes to meet their production requirements.

Core Equipment and Processes

The production line covers full-process automation equipment from raw material processing to finished product packaging:

- Intelligent mixing system: A horizontal dough mixer is used to ensure that flour, water and auxiliary materials are evenly mixed to improve fermentation efficiency.

- Precise sheeting and forming: The three-roller sheeting machine presses the dough into uniform thin sheets, and is equipped with a stamping or roller cutting machine to flexibly adapt to a variety of biscuit shapes (such as square and round). The mold is made of stainless steel, which is corrosion-resistant and easy to replace.

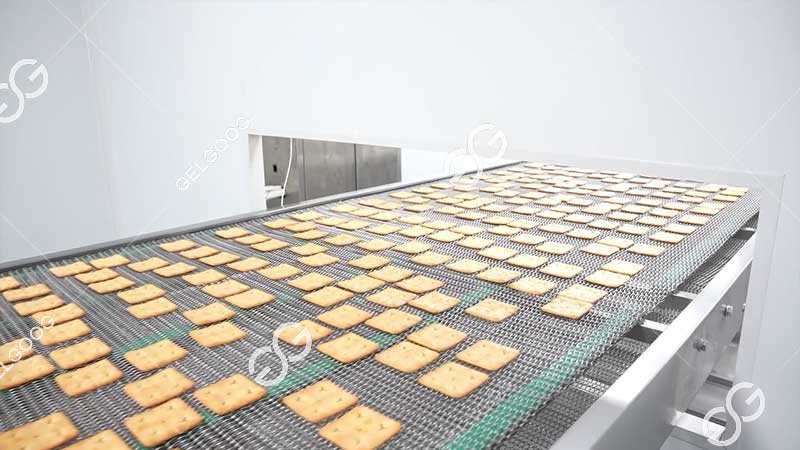

- Efficient baking and cooling: The tunnel oven (electric heating or gas) achieves precise temperature control, and cooperates with a multi-layer cooling conveyor belt to ensure the crispy taste of the biscuits.

- Automated packaging: pillow or vertical packaging machines support packaging of various specifications, and vacuum sealing technology extends shelf life and reduces oxidation risks.

Core Advantages of the Cracker Production Line

- Efficiency improvement: The automated process enables continuous production, with a production capacity of 500-1200kg/h, and a 30% reduction in labor costs.

- Flexible customization: Modular design supports equipment expansion, and biscuits of different flavors (original, onion, sesame) and shapes can be produced by replacing molds to meet diverse market needs.

- Sanitation and safety: The entire line uses food-grade SUS304 stainless steel, combined with a closed production environment, in line with international food safety standards.

- Stable quality: Standardized processes ensure that the weight and thickness of each biscuit are consistent, helping to establish a brand image

Applicable Scenarios and Customer Value

- Startups and small and medium-sized factories: You can choose a medium-sized production line of 500-800kg/h, with flexible investment and rapid production.

- Large food groups: 1200kg/h high-capacity configuration, with intelligent temperature control and waste recycling systems to reduce overall costs.

- Diversified market expansion: Support the development of salty, sweet and special flavors (such as high fiber, black sesame), covering supermarkets, catering and healthy snacks.

Reasons to Choose Us

- Technical guarantee: A team of engineers with 30 years of industry experience, providing one-stop service from equipment installation to process training.

- Global case verification: Customer feedback shows that the production line has helped increase the order volume by 350%, and the product qualification rate exceeds 99%.

- Customized support: Design exclusive solutions according to enterprise needs and provide a 1-year core component warranty.

Leave A Message To Get A Quote

Click to rate this post!

[Total: 3 Average: 5]

Reviews

There are no reviews yet.