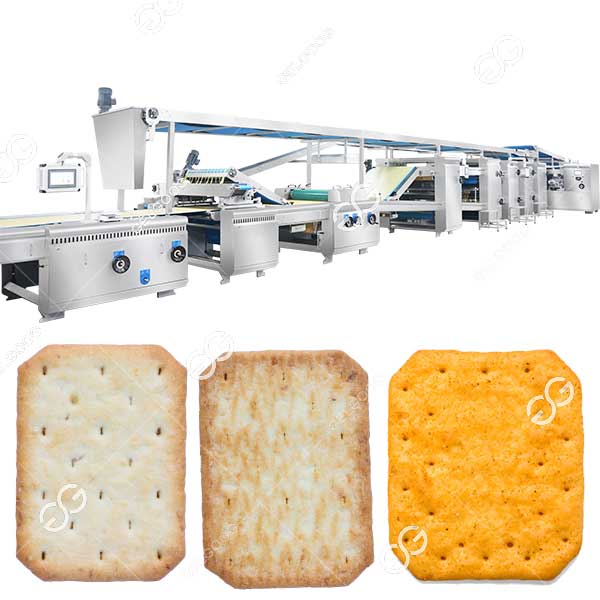

The industrial saltine cracker production line has become the core weapon for enterprises to reduce costs and increase efficiency with its full process automation, high-capacity design, and flexible formula support!

As a top manufacturer in the industry, we provide you with a one-stop solution from raw material mixing to packaging to meet the diverse needs of enterprises of different sizes.

Advantages of Industrial Saltine Cracker Making Machine

- Full process automation: high-quality electrical components are used to achieve precise control of temperature, speed, and filling volume to ensure product thickness and taste consistency.

- Integrated design: integrated mixing, molding, baking, cooling, packaging and other modules to reduce manual intervention, with a production capacity of 150-5500 kg/hour, suitable for small factories to large industrial production.

- Precision baking system: The tunnel furnace is driven by electric heating or gas, and the temperature is controlled in different zones (forming area, baking area, coloring area) to ensure that the biscuits are crispy and uniform, and the color is golden.

- Food grade material guarantee: The contact surface of the equipment is made of 304 stainless steel, and the transmission parts are equipped with NSK bearings and food-grade PU conveyor belts, which comply with HACCP and ISO 9001 certification to eliminate contamination risks.

Saltine Cracker Making Machine High Flexibility

- Formula and process support: Provide customized formula debugging services, support soda crackers, sandwich crackers, ultra-thin crackers and other categories of expansion.

- Modular expansion: The production line layout can be customized according to the plant space, and additional functions (such as automatic oil spraying, powdering, packaging and sorting) can be upgraded to increase added value.

- Quick mold change technology: Support flexible mold replacement, can produce square, round, wavy and other salt cracker forms, seamlessly switch different flavors (such as original, cheese, spicy, etc.).

Technical Parameters and Performance Highlights

| Key modules | Technical specifications and advantages |

| Raw material mixer | Power 5.5kW, mixing time 10-15 minutes, 304 stainless steel hopper, support uniform mixing of dry and wet raw materials. |

| Forming machine | Servo-driven cutting, forming accuracy ±0.2mm, support fast mold change, production capacity 150-200 kg/hour. |

| Tunnel oven | Length 20 meters, 5-zone temperature control, electric heating power 100-120kW, gas type thermal efficiency up to 85%. |

| Packaging system | Fully automatic sorting and packaging, speed 40-230 bags/minute, supports vacuum, nitrogen filling and other packaging forms. |

Why Do Global Customers Choose Us?

✅ Decades of technology accumulation, leading equipment stability in the industry;

✅ 100+ countries service experience, in-depth understanding of local needs;

✅ Full escort from R&D to after-sales, so that investment has no worries.

Take action now and start a new era of efficient production!

Leave a message to consult and get:

Customized production line planning plan (including 3D layout diagram);

Successful case video of similar customers;

Leave A Message To Get A Quote

Reviews

There are no reviews yet.