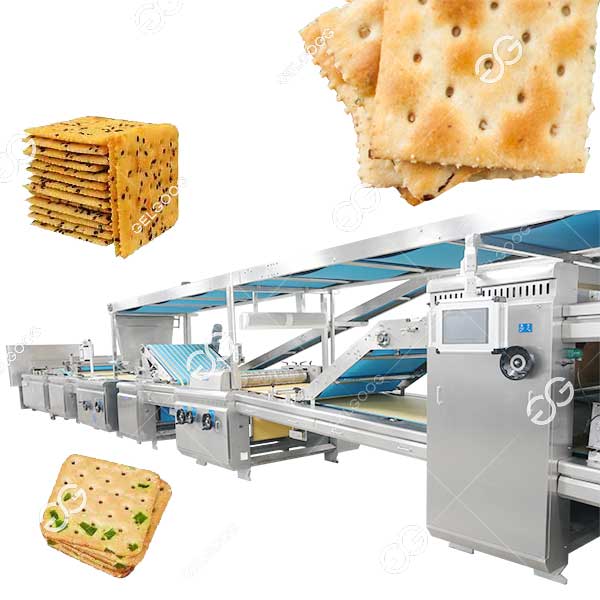

Hard biscuit production equipment has achieved a high degree of automation, from dough preparation, molding, baking to packaging, greatly reducing manual intervention and improving production efficiency.

Composition of Hard Biscuit Production Equipment

Each component of the production line is engineered to work in synergy, ensuring smooth and consistent output. Below is a detailed breakdown of key equipment:

- Dough mixer: used to mix the raw materials evenly to make dough suitable for hard biscuit production. Dough mixers are divided into vertical and horizontal types, and their mixing speed and time are adjustable to ensure the uniformity and consistency of the dough.

- Dough conveyor: conveys the kneaded dough to the subsequent molding equipment to ensure the continuity of production.

- Dough rolling machine: presses the dough into uniform dough sheets to prepare for the subsequent molding process.

- Laminating machine: by folding and flattening the dough sheets multiple times, the biscuits have a layered feel, which is suitable for the production of multi-layer hard biscuits.

- Rotary molding machine: uses a rotating mold to cut the dough sheets into biscuit blanks of various shapes, with high production efficiency, and can produce hard biscuits of various shapes and patterns.

- Wire cutting machine: cuts the dough sheets into biscuit blanks through steel wire, which is suitable for the production of some simple hard biscuit shapes.

- Tunnel oven: It is the key to hard biscuit production equipment. It usually adopts hot air circulation heating method, which can bake biscuits evenly and ensure the color and taste of biscuits.

- Oven front conveyor and oven rear conveyor: They are used to send biscuit blanks into the oven and send baked biscuits out of the oven respectively.

- Cooling conveyor: Prevent biscuits from deforming or deteriorating due to high temperature before packaging. Cooling conveyor usually adopts natural cooling or forced ventilation cooling.

- Oil sprayer: Spray a layer of edible oil on the surface of biscuits to increase the gloss and taste of biscuits, and at the same time play a certain role in preservation.

- Biscuit sorting machine: Sort the cooled biscuits and arrange them neatly for subsequent packaging.

- Packaging machine: Pack the sorted biscuits. Common packaging forms include pillow packaging, box packaging, etc. The packaging machine can realize automatic packaging and improve production efficiency.

Key Advantages of Hard Biscuit Production Equipment

- 24/7 Continuous Production: The equipment can achieve 24-hour uninterrupted operation. As long as the raw material supply is sufficient, the production line can continue to work, reducing downtime and improving equipment utilization.

- Standardized Production & Consistent Quality: The forming equipment in the hard biscuit production equipment can accurately cut the biscuit blanks to ensure that the shape, size and thickness of each biscuit are consistent, thereby ensuring the stability of product quality.

- Strong Product Adaptability:Quick-change components (molds, nozzles, packaging films) allow product switching in under 30 minutes, enabling businesses to respond fast to market trends (e.g., healthy snack demands) without investing in new equipment. The line accommodates diverse recipes and product types:

Through high automation, precise control and flexible design, hard biscuit production equipment not only improves production efficiency and product quality, but also reduces production costs and labor intensity, providing reliable technical support for the production of hard biscuits.

Conclusion

Leave A Message To Get A Quote

Click to rate this post!

[Total: 0 Average: 0]

Reviews

There are no reviews yet.