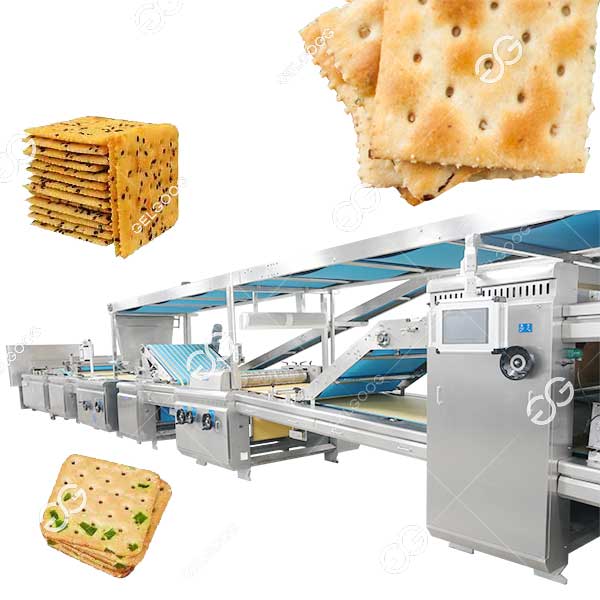

Fully automatic biscuit making machine does not require a lot of manual intervention from the precise delivery of raw materials to the mixing and shaping of dough, and finally baking out of the oven. It is designed for large-scale production of biscuits in factories.

Automatic Biscuit Making Machine Structure Analysis

- Raw material delivery system: equipped with high-precision electronic scales and automatic feeding devices, it can accurately put flour, sugar, oil and other raw materials into the mixing tank in sequence according to the preset formula, laying a good foundation for subsequent processes.

- Mixing and molding unit: The powerful stirring blades fully mix the raw materials into a uniform dough, and then extrude and cut them through special molds to shape various exquisite biscuit shapes, such as round, square, animal shapes, etc.

- Baking system: Fully automatic biscuit making machine adopts advanced temperature control technology to simulate the baking environment of traditional ovens, accurately control temperature, humidity and time, ensure that the biscuits are evenly heated from the inside to the outside, and achieve a perfect golden and crisp taste.

- Transportation and packaging connection: The finished biscuits are orderly output through the conveyor belt, and can be directly connected to the packaging equipment to realize a fully automated production process, reduce manual handling links, and further improve production efficiency.

Advantages of Fully Automatic Biscuit Making Machine

- Super high efficiency: Compared with traditional manual or semi-automatic equipment, the production speed of fully automatic biscuit making machine is amazing. It can produce a large number of biscuits with stable quality in a short time, meet the market’s growing demand for biscuits, greatly shorten the production cycle, and help enterprises seize the market opportunity.

- Stable quality: With a precise control system, the weight, shape, and baking degree of each biscuit can be highly consistent. Whether it is taste or appearance, consumers can enjoy a standardized high-quality experience and establish a good reputation for the brand.

- Save manpower: In the past, many workers were required in various production links, but now automatic biscuit making machine only needs a few operators. This not only reduces labor costs, but also reduces quality problems caused by human factors, making production management easier and more efficient.

- Versatility: By changing molds, adjusting parameters, etc., you can easily make various types of biscuits, such as cream biscuits, soda biscuits, sandwich biscuits, etc., to meet the taste preferences of different consumers and broaden the market coverage of products.

With its excellent performance, the fully automatic biscuit making machine has become an indispensable tool in the modern biscuit production industry. If you want to know more details, please feel free to contact our professional team, we will serve you wholeheartedly!

Leave A Message To Get A Quote

Click to rate this post!

[Total: 1 Average: 5]

Reviews

There are no reviews yet.