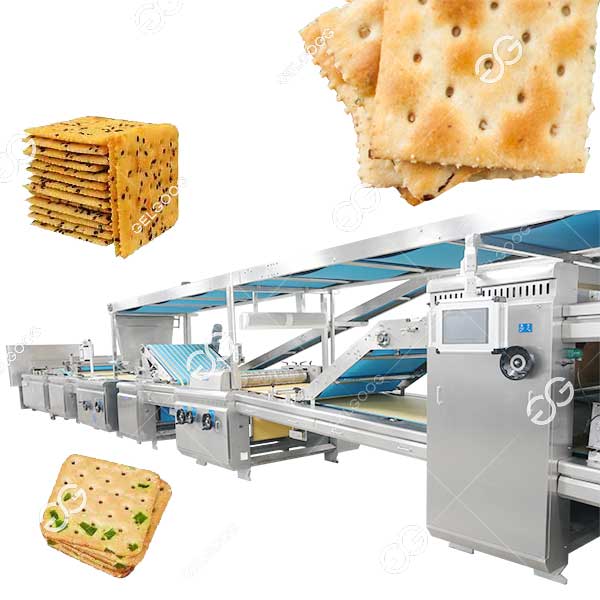

The digestive biscuit production line serves as an all-encompassing machinery setup designed for the large-scale and efficient manufacturing of digestive biscuits.

It consolidates a multitude of intricate production stages, spanning from the introduction of raw materials to the packaging of the final products, thereby facilitating automated and uninterrupted production. This ensures the consistent output and stable quality of digestive biscuits.

In-Depth Look: The Digestive Biscuit Manufacturing Process

Our production line is meticulously designed to handle each critical stage of biscuit creation:

-

Automated Raw Material Handling

Ingredients like whole wheat flour, sugar, and fats are precisely conveyed from storage silos to the processing area via pneumatic systems, conveyor belts, and screw feeders. Advanced metering systems ensure each ingredient is dispensed with absolute accuracy according to the recipe. -

Precision Dough Mixing

The pre-mixed ingredients are transferred to a high-capacity dough mixer (such as a double-shaft paddle mixer or horizontal spiral mixer). This stage is crucial for developing a homogeneous, well-hydrated dough with the perfect consistency for forming. -

Flexible Forming and Shaping

The dough is then shaped by either a rotary molding machine or a wire-cut machine. These machines feature interchangeable molds and dies, offering exceptional flexibility to produce digestive biscuits in various shapes, sizes, and intricate designs to meet market trends. -

Uniform Baking and Cooling

The shaped biscuits travel through a multi-zone tunnel oven. This oven features precisely controlled pre-heating, baking, and cooling zones. The result is even baking, optimal color development, and a characteristically crisp texture, all while accommodating different biscuit shapes.

Digestive Biscuit Production Line Advantages

-

High-Volume Output: Achieve mass production targets with ease. Our tightly integrated lines can produce thousands of kilograms per hour, enabling you to fulfill large orders and secure a dominant market position.

-

Recipe Consistency and Flexibility: Our sophisticated control system guarantees precise ingredient ratios in every batch. It also allows for quick and easy recipe modifications, letting you adapt to evolving consumer tastes without downtime.

-

Superior End-Product Quality: Automated control over mixing, baking, and cooling ensures every biscuit has the same perfect taste, texture, and appearance, strengthening your brand’s reputation for quality.

-

Easy Operation and Maintenance: Designed with hygiene and uptime in mind, the equipment features a streamlined structure with minimal dead spaces. This simplifies daily cleaning, reduces waste buildup, and facilitates routine maintenance.

FAQ About Digestive Biscuit Production Plant

Q: What is the difference between using whole wheat flour and regular flour in digestive biscuits?

A: Using whole wheat flour significantly increases the dietary fiber content and enhances the satiety value of the biscuits, positioning them as a healthier option. In contrast, biscuits made with regular (refined) flour have a more delicate, tender texture and a milder flavor but contain less fiber.

Q: How do baking temperature and time affect the final quality of digestive biscuits?

A: Precise baking is critical. Excessively high temperature or prolonged baking will cause the biscuits to burn, lose too much moisture, and become hard, brittle, and bitter. Conversely, insufficient temperature or baking time will result in undercooked, pale, and soft biscuits that lack crispness and have a reduced shelf life due to higher moisture content.

Q: What does routine cleaning and maintenance involve for the production line?

A: We recommend implementing a structured cleaning and maintenance schedule. This includes daily cleaning of conveyors, mixers, and molds to prevent residue buildup, along with regular lubrication of moving parts, calibration of sensors and thermostats, and inspection of electrical components. This proactive approach ensures consistent performance and extends the equipment’s operational life.

Leave A Message To Get A Quote

Reviews

There are no reviews yet.