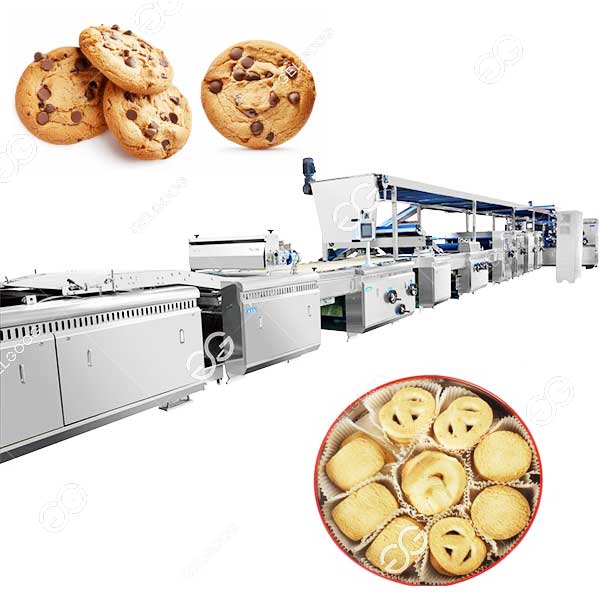

Cookie manufacturing equipment can provide cookie manufacturers with consistent quality, high efficiency and production versatility, and is an indispensable equipment for small factories and large-scale industrial production.

Key Components and Features of Cookie Manufacturing Equipment

- Dough mixing equipment: The continuous mixing system can eliminate the inconsistency of dough between batches and provide consistent and repeatable dough all day long.

- Forming equipment: There are many types of cookie forming equipment, such as wire cutters and rotary forming machines. Different forming equipment is used according to the different products produced. At the same time, we provide customized forming systems, and set different patterns according to your desired settings.

- Baking equipment: Industrial baking equipment mainly includes hot air rotary ovens and tunnel baking machines. The tunnel baking machine is often used in large cookie production plants due to its high output and continuous production characteristics, and is the first choice for cookie manufacturing equipment.

- Cooling and conveying equipment: It is used to cool the baked cookies to a temperature suitable for packaging, and to smoothly transfer the cookies from one production stage to the next.

- Packaging equipment: It realizes the automatic packaging of cookies to ensure the sealing and shelf life of the products.

Advantages of Using Cookie Manufacturing Equipment

- Consistency and quality: Automated mixing and forming processes ensure uniform size, shape and texture of each batch of cookies.

- High productivity: These machines can produce thousands of cookies per hour, making them ideal for large-scale production.

- Versatility: The equipment can be adjusted to different production needs, such as changing molds or cutting devices to produce cookies of different shapes and sizes.

- Labor saving: Automation reduces the need for labor, reduces production costs, and improves efficiency.

- Energy saving and efficiency: Energy consumption is reduced while maintaining optimal baking conditions through optimized heating elements and insulation materials.

- Sanitation and cleaning: The equipment is designed for ease of cleaning and maintenance, and uses materials that are easy to clean and disinfect, meeting food safety standards.

Choosing the Right Equipment

When choosing cookie manufacturing equipment, consider factors such as production capacity, the type of cookies required, and budget. Whether you need a wire cutter for simple shapes or a rotary molder for complex designs, we can provide you with a tailor-made solution.

If you have further needs or questions, please feel free to contact us. We can provide detailed solutions and quotations based on your specific needs to help you achieve efficient production goals.

Leave A Message To Get A Quote

Click to rate this post!

[Total: 0 Average: 0]

Reviews

There are no reviews yet.