The automated compressed biscuit production line is a complete, highly automated industrial solution designed specifically for producing high-density, long-lasting, high-energy compressed biscuits (such as military biscuits, emergency food, and outdoor energy bars).

Process Overview

- Dough Preparation and Initial Baking: Raw materials are mixed into a uniform dough using a high-speed mixer, then shaped into initial forms (such as small biscuit strips or granules) using a roller mill, cutter, or extruder. The dough is then initially baked in a tunnel oven to set its shape and develop initial crispness and aroma.

- Grinding and Particle Size Control: After cooling, the baked semi-finished product enters a controlled grinder. By adjusting the grinding parameters, uniformly sized biscuit crumbs that meet the required specifications are obtained. This step creates the unique granular texture foundation of the product.

- Mixing and Binder Addition: The biscuit crumbs are evenly coated with syrup, oil, nutrients, or flavor enhancers in a mixer. The added binder (such as syrup) is crucial for subsequent compression molding, ensuring the crumbs are firmly bound together.

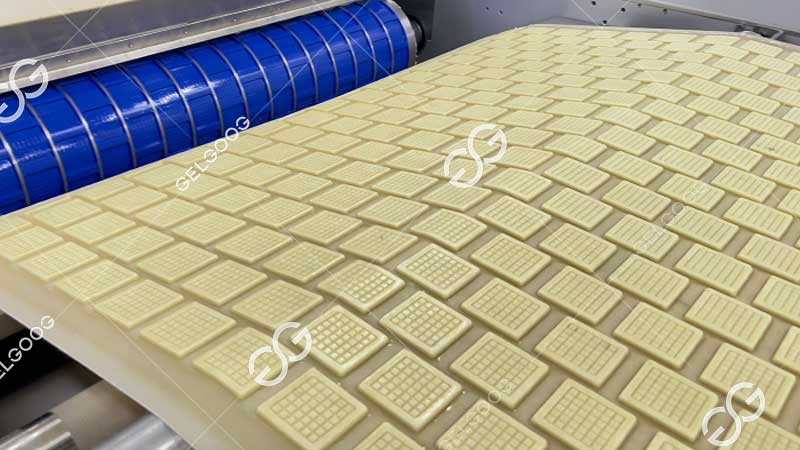

- Secondary Compression Molding: The mixed materials are fed into a medium-sized compression molding machine and pressed into the final block shape (e.g., rectangle, round) in a mold. The pressure here is much lower than in traditional compressed biscuits, designed to bind rather than be extremely dense, thus preserving a crisp texture and airy feel.

- Cooling and Final Packaging: The shaped products enter a cooling tunnel to allow the binder to solidify and set. They are then individually sealed by a high-speed pillow packaging machine or cartoning machine to ensure crispness and extend shelf life.

The Preferred Choice for Professional Manufacturers

- True Turnkey Project and Process Support: We provide full-process support from formula testing and process design to equipment delivery, installation, and commissioning, ensuring you can consistently produce high-quality compressed biscuits that meet standards.

- Extremely High Energy and Space Efficiency: The production line has a compact layout, high thermal energy recycling rate, and low unit energy consumption. High automation requires only a few people to operate a single line, resulting in extremely high per capita output.

- Product Consistency and Safety: Automated production eliminates human variation, ensuring that the weight, density, moisture content, and nutritional composition of each biscuit are highly consistent. The fully enclosed production process maximizes food hygiene and safety.

Why Choose Us?

- In-depth Process Understanding: We not only provide equipment, but also possess profound knowledge of the material properties and formulation processes of compressed biscuits, offering key process parameter suggestions and optimization solutions.

- Strong Customization Capabilities: We can customize complete production lines according to your product specifications (shape, weight, formula complexity) and production capacity requirements (e.g., 500kg/hour – 2000kg/hour).

- Global Project Experience: Our production lines have served numerous outdoor food manufacturers worldwide, and the reliability and durability of our equipment have been rigorously verified.

Frequently Asked Questions

Q: Can this production line produce compressed biscuits of different shapes and sizes?

A: Absolutely. Interchangeable molds are used in the molding stage. We can design and provide molds of various shapes (round, square, rectangular) and sizes. Changing molds is a relatively quick process, allowing for easy switching between different products.

Q: What is the shelf life of the biscuits produced by this production line?

A: High-pressure molding and controlled baking processes significantly reduce the moisture content of the biscuits, making them denser and less prone to spoilage and decay. With proper gas filling or vacuum packaging (which we can provide), the shelf life can typically be extended to 2-3 years or even longer under suitable storage conditions.

Reviews

There are no reviews yet.