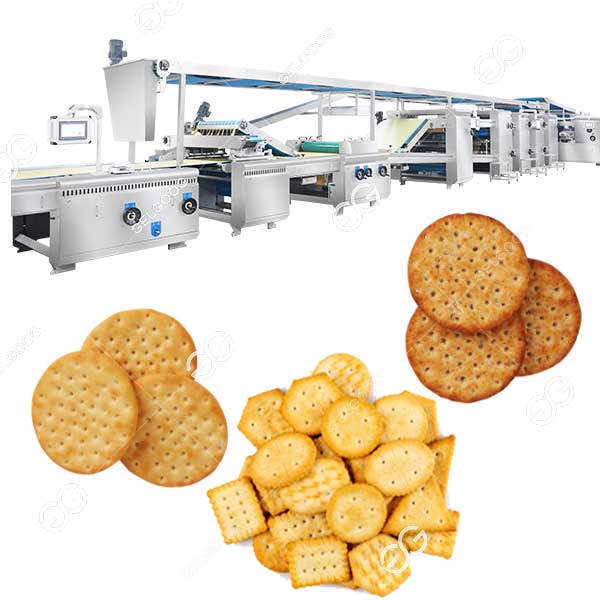

As a biscuit production line manufacturer, we focus on providing industrial-grade equipment to meet the stringent requirements of large factories and enterprises.

Industrial Biscuit Production Line Process

Sieving powder – kneading dough – pressing – forming – baking – oil spraying – cooling – arranging cakes – filling/filling – packaging

Fully Automatic Biscuit Production Line Composition

- Dough mixer: used to mix flour, water, sugar, oil and other raw materials evenly to make dough suitable for biscuit production. Depending on the type of biscuits, you can choose a vertical dough mixer or a horizontal mixer

- Biscuit forming machine: press the kneaded dough into sheets, and then cut and shape them through molds or rolling cutters to produce biscuits of various shapes and sizes

- Tunnel baking oven: the biscuits pass through the tunnel oven on the conveyor belt, and the baking process is completed after preheating, baking, coloring and other stages. The heat source can be electricity, gas, natural gas, etc.

- Oil sprayer: spray oil on the surface of biscuits to increase gloss and taste

- Cooling conveyor: used to cool the baked biscuits to room temperature. The cooling method can be natural cooling or forced cooling

- Biscuit sorting machine: sort and arrange the cooled biscuits for subsequent packaging

- Packaging machine: sort and package the biscuits to ensure the hygiene and freshness of the products during transportation and sales

Our Core Advantages

As a professional biscuit production line manufacturer, Whether you are expanding an existing facility or building a new project, our solutions can meet high-volume needs. We provide:

- Fully automated production lines: One-stop production from raw materials to packaging, maximizing labor savings

- Optimal energy consumption: Optimize energy and raw material utilization in each production link to provide you with the best cost-saving and efficiency-enhancing solutions

- Multiple uses for one line: A single solution is suitable for the production of multiple products, and the versatility meets your creativity

- Additional production processes: Not only can we customize production line solutions for you, but we can also match production process technologies to solve your production problems in one stop

- Full-range services: From production line design, machine manufacturing, assembly and commissioning to after-sales, 24-hour service without worries

Frequently Asked Questions

Q: Can your lines handle gluten-free or organic biscuit production?

A: Yes! Our systems support allergen-free recipes and comply with organic certification requirements.

Q: What’s the typical ROI for a fully automated line?

A: Most clients achieve breakeven within 12–18 months via reduced waste and labor costs.

Q: Do you provide turnkey solutions?

A: Absolutely—we manage design, installation, and commissioning for seamless integration.

Reviews

There are no reviews yet.