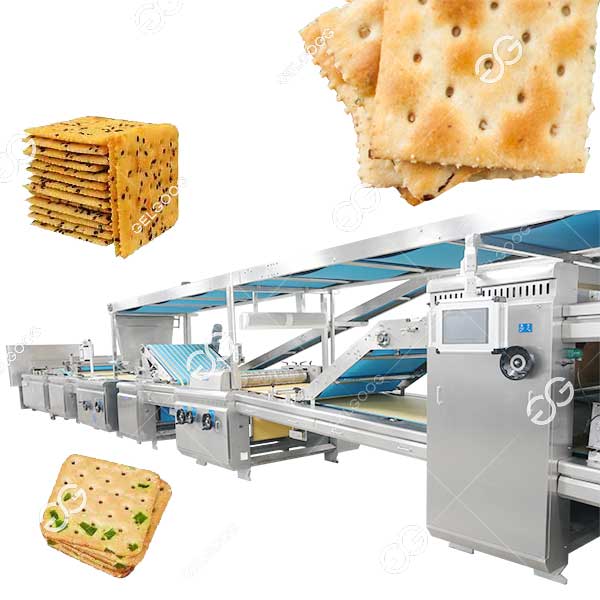

The biscuit processing line is a fully integrated system designed for large-scale production, covering multiple stages from dough mixing to packaging.

Biscuit Processing Line Core Components

- Dough kneading machine: A large-capacity dough kneading machine with programmable control ensures a uniform texture.

- Forming machine: A rotary former or a wire-cut former for forming biscuits.

- Tunnel oven: A multi-zone energy-saving baking system with uniform temperature.

- Cooling conveyor: Automatic cooling ensures a crispy texture before packaging.

- Packaging unit: A pillow wrapper or cartoner for airtight sealing.

Biscuit Processing Line Process

- Raw material preparation and mixing: The raw materials are precisely metered and a spiral mixer, planetary mixer or continuous mixer is used to ensure uniform mixing.

- Dough forming and shaping: Depending on the type of biscuit, the dough is rolled into sheets, cut into various shapes or placed in molds.

- Baking: The formed biscuits are fed into an industrial oven for baking to achieve the desired crispness and color. Use a tunnel oven (gas or electric) with precise temperature and airflow control.

- Cooling: Biscuits need to be cooled after baking to stabilize their texture and prevent moisture problems during packaging.

- Packaging: Biscuits are packaged using pillow packaging machines or automated packaging lines to maintain freshness and enhance shelf appeal.

Factors Affecting Biscuit Production Line Price

- Production capacity: The larger the production capacity, the higher the price. Small production lines can produce hundreds of kilograms of biscuits per hour, while large production lines can produce several tons per hour

- Degree of automation: Fully automated production lines are more expensive, but they can reduce labor costs and improve production efficiency

- Equipment quality: High-quality materials (such as food-grade stainless steel) and advanced features (such as automatic temperature control and humidity sensors) make equipment more expensive

- Brand and reputation: Well-known brands are usually more expensive, but the quality and service are more guaranteed

- Customization requirements: Customization requirements for special shapes, patterns or processes will increase costs

If you are interested in setting up a biscuit processing line, we can provide you with a comprehensive solution based on your production goals, budget and needs.

The following is the range of services and products we can provide to ensure that your production line can run efficiently and meet your production goals:

- Production target assessment: Based on your market needs and expected output, we help you determine the size and configuration of the production line.

- Budget planning: According to your budget, we provide a variety of equipment options and configuration solutions to ensure maximum cost-effectiveness.

- After-sales service: Provide long-term after-sales support, including equipment maintenance, parts supply and technical consultation, to ensure the long-term stable operation of the production line.

- One-stop service: From production line design, equipment procurement, installation and commissioning to production and operation, we provide one-stop turnkey services to help you quickly start production.

Leave A Message To Get A Quote

Click to rate this post!

[Total: 0 Average: 0]

Reviews

There are no reviews yet.