In the field of biscuit production, biscuit processing equipment is the key to ensuring product quality, improving production efficiency and meeting market demand.

We are committed to providing global biscuit manufacturers with comprehensive and high-performance biscuit processing equipment, from raw material processing to finished product packaging, aiming to help customers achieve efficient, stable and flexible production operations while meeting diverse market needs.

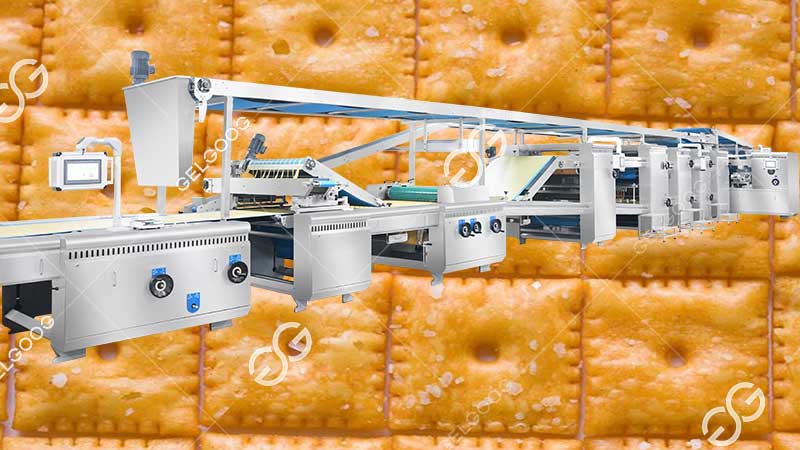

Composition of Biscuit Processing Equipment

- Process flow: raw material warehouse → batching system → mixer → proofing chamber → forming machine → baking oven → cooling belt → detector → packaging line → finished product warehouse

- Raw material processing system: including automatic batching machine, vacuum suction system, and liquid quantitative injection device. Realize the automatic proportioning and pretreatment of raw materials, ensure the consistency of formula, and reduce manual errors.

- Dough mixing and proofing equipment: including double-axis horizontal mixer and constant temperature proofing chamber. It can evenly mix the dough to avoid imbalance of gluten caused by excessive kneading.

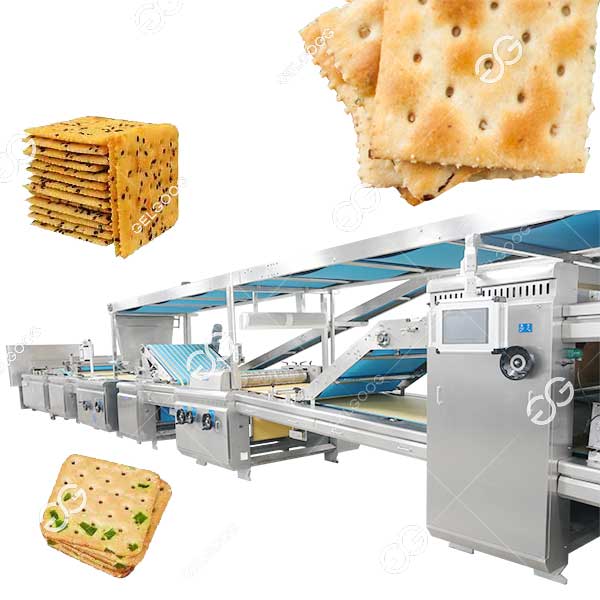

- Biscuit forming unit: including roller printing forming machine, stamping forming machine, and extrusion forming machine. It has a quick mold replacement system (switching can be completed within 10 minutes).

- Baking and cooling system: including multi-layer tunnel baking oven, automatic oil spraying/sugar sprinkling device, cooling conveyor belt. It can accurately control the dehydration rate of biscuits to avoid cracking or deformation.

Core Advantages of Biscuit Processing Equipment

Multi-function dough forming machine

- Supports various forming processes such as roller printing, stamping, extrusion, etc., with a thickness adjustment accuracy of ±0.1mm.

- Equipped with self-cleaning device to reduce raw material residue when switching products.

Tunnel energy-saving baking oven

- Zoned temperature control technology (adjustable from 80-300℃) adapts to the dehydration curve of biscuits with different moisture contents.

- The thermal efficiency is increased to 75%, shortening the baking time by 15% compared with traditional equipment.

How to Customize Your Biscuit Processing Equipment?

Our engineering team provides three-step customization service:

- Demand analysis: plan equipment combination according to product type, target production capacity and budget.

- Solution verification: demonstrate production line layout and operation logic through 3D simulation.

- Local support: global 48-hour response mechanism, providing installation training and lifelong maintenance.

By modularizing Biscuit Processing Equipment, companies can build efficient and intelligent production lines to meet the needs of diversified product development while reducing costs and increasing efficiency.

Whether you are building a new factory or upgrading an existing production line, Biscuit Processing Equipment can provide reliable protection for your company. If you need to obtain a specific equipment configuration plan, please contact our engineering team for customized design!

Reviews

There are no reviews yet.