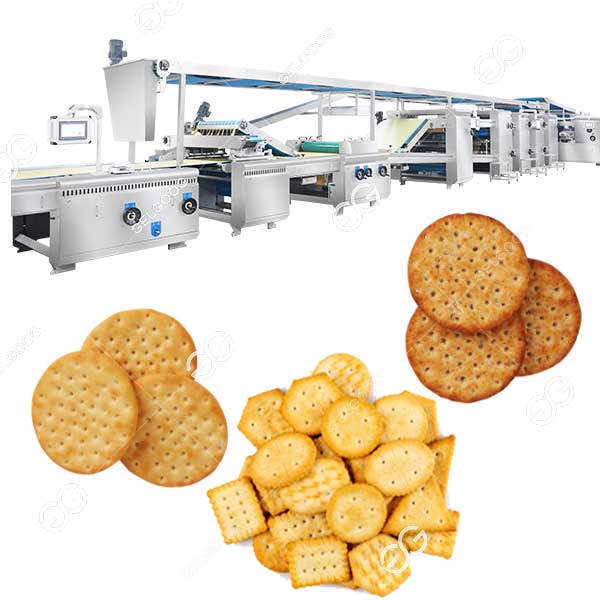

Our Automatic Wheat Cracker Machine represents cutting-edge technology for industrial cracker production. Designed for manufacturers scaling their snack production, this complete production line delivers end-to-end automation from ingredient mixing to final packaging. With capacity ranging from 100-1200 kg/hour, it ensures consistent quality, maximum efficiency, and adaptability to market trends.

Why Choose Our Automatic Wheat Cracker Machines?

Our machines integrate end-to-end automation, from raw material processing to packaging, ensuring unmatched consistency and scalability. Here’s why they are the industry’s top choice:

1. Intelligent Automation & Precision Control

- PLC control system with user-friendly HMI interface

- Real-time monitoring of temperature (±1°C), humidity, and dough thickness

- Automated adjustments for consistent texture, color, and taste across batches

- Predictive maintenance alerts reducing unplanned downtime by 40%

2. High-Speed Production Capability

- Production capacity: 100-1200 kg/hour (model dependent)

- 10x faster than traditional production methods

- Continuous operation with automatic feeding and discharge systems

- Quick changeover between products (under 15 minutes)

3. Product Versatility & Customization

-

Quick mold switching for multiple shapes (round, square, heart, custom)

-

Adaptable recipes for various cracker types:

- Classic salted crackers

- Whole grain and high-fiber variants

- Low-sodium and health-focused options

- Gourmet crackers with inclusions (seeds, herbs, spices)

-

Customizable thickness from 1-5mm

4. Energy Efficiency & Sustainability

-

Multiple heating options: Electric, gas, or hybrid systems

-

Heat recovery technology reducing energy consumption by 25-30%

-

Waste minimization through precise dough cutting and recycling

-

Energy-efficient motors with IE4 classification

Wheat Cracker Machine Technical Specifications

Production Line Models Comparison

| Model | Capacity (kg/h) | Oven Width | Power Consumption | Floor Space |

|---|---|---|---|---|

| GG-BG400 | 100-400 kg/h | 400-600mm | 45-65 kW | 15×3×2.5m |

| GG-BG700 | 400-700 kg/h | 600-800mm | 75-95 kW | 22×3.5×3m |

| GG-BG1200 | 700-1200 kg/h | 800-1200mm | 110-140 kW | 30×4×3.5m |

Ideal for Diverse Market Applications

-

Snack Food Producers: Deliver bulk quantities of uniform, crispy wheat crackers to retail and supermarket chains.

-

Bakery & Café Suppliers: Produce artisalian-style crackers that pair perfectly with cheeses, dips, or specialty beverages.

-

Health-Conscious Brands: Develop low-fat, high-fiber, or reduced-sodium crackers tailored to today’s nutritional trends.

Key Competitive Advantages

-

Reduce Operating Costs: Cut labor requirements by up to 70% and minimize material waste through precision dosing and process control.

-

Accelerate Time-to-Market: Launch new flavors, shapes, or recipes in days—not weeks—staying ahead of consumer preferences.

-

Certified for Global Export: Comply with ISO, HACCP, and other international standards for seamless market entry.

Partner with GELGOOG for Smarter Wheat Cracker Machine

More than just a machine—our Automatic Wheat Cracker Machine is your strategic partner in growth. By integrating automation, adaptability, and energy-efficient performance, we help you elevate quality, expand capacity, and grow your business sustainably.

Case Study: Successful Implementation

Client: European Snack Manufacturer

Challenge: Increase production capacity while maintaining artisanal quality

Solution: GG-BG700 Automatic Wheat Cracker Line

Results:

-

Production capacity increased from 200 kg/h to 650 kg/h

-

Labor costs reduced by 65%

-

Product consistency improved (reject rate reduced from 5% to 1.2%)

-

ROI achieved in 14 months

Ready to transform your cracker production line?

Contact our engineering team today to discuss a customized solution:

📧 Email: shanna@machinehall.com

📞 Phone: +86 18638676709

Leave A Message To Get A Quote

Reviews

There are no reviews yet.