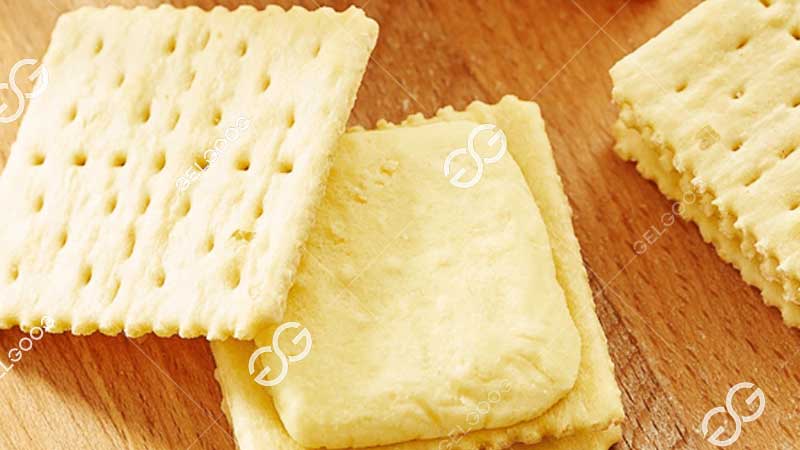

Automatic Sandwich Cracker Production Line

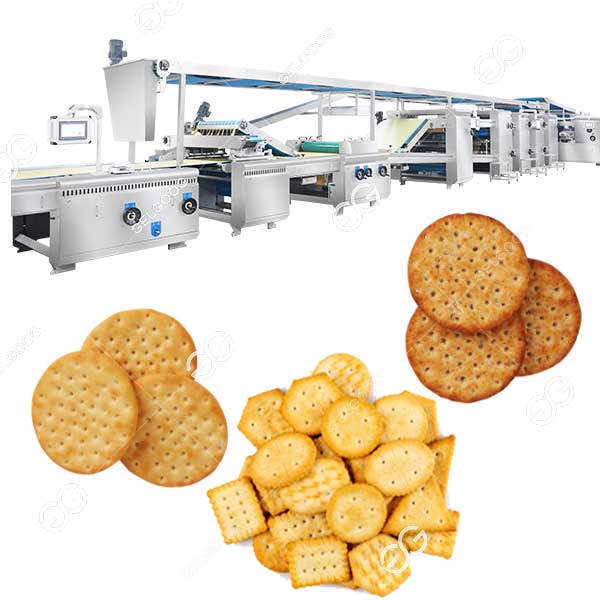

The production line consists of a raw material processing system, including storage, weighing, and conveying equipment; a dough preparation system, including mixing and proofing devices; a biscuit forming machine; a filling system, including storage and precise filling equipment; a baking oven; a cooling, packaging system, and an intelligent control system.

Customer Value Brought by Sandwich Cracker Production Line

- Fast and continuous production: The automated production line can achieve 24-hour uninterrupted production. Compared with manual production, the efficiency is greatly improved, which can effectively shorten the production cycle and meet the rapid growth of the market demand.

- Reduced labor costs: Reduced dependence on a large number of manual labor, an automated production line only requires a few operators to monitor and maintain, reducing labor costs and management costs, and improving the economic benefits of the enterprise.

- Precise control of process parameters: The baking temperature, time, sandwich amount and other key parameters of the biscuits can be accurately controlled to ensure that the taste, flavor and appearance of each sandwich biscuit are highly consistent, improve the stability and reliability of the product, and enhance consumers’ trust in the brand.

- Compliance with food safety standards: In the fully automated production process, the contamination of products by human factors is reduced, the production environment is more hygienic, the production process is more in line with food safety standards, and the food safety risks are reduced.

Automatic Sandwich Cracker Production Line Applicable Scenarios

- Large-scale production of food processing enterprises: Suitable for large-scale food factories, which can meet the needs of large-scale sandwich biscuits produced daily, such as production factories of brands such as Danone and Oreo, using automated production lines to achieve efficient and stable large-scale production, ensuring the timeliness and adequacy of product supply.

- Capacity expansion and quality improvement of medium-sized food enterprises: For medium-sized food enterprises with a certain scale and who want to expand their production scale and improve the stability of product quality, the automated sandwich biscuit production line can ensure the consistency of indicators such as weight, sandwich volume, and baking degree of each sandwich biscuit while increasing production capacity, which helps to enhance brand image and market competitiveness.

- Customized production of pastry shops and small food factories: Some pastry shops or small food factories that focus on product characteristics and personalization can use this production line to customize small batches and multiple varieties of sandwich biscuits.

Leave A Message To Get A Quote

Click to rate this post!

[Total: 2 Average: 5]

Reviews

There are no reviews yet.