The global market for automatic sandwich cracker making machines is growing rapidly, driven by the growing demand for convenience foods and the need for efficient production processes.

We continuously invest in R&D to introduce more advanced features such as improved automation, digital control and eco-friendly design, among others.

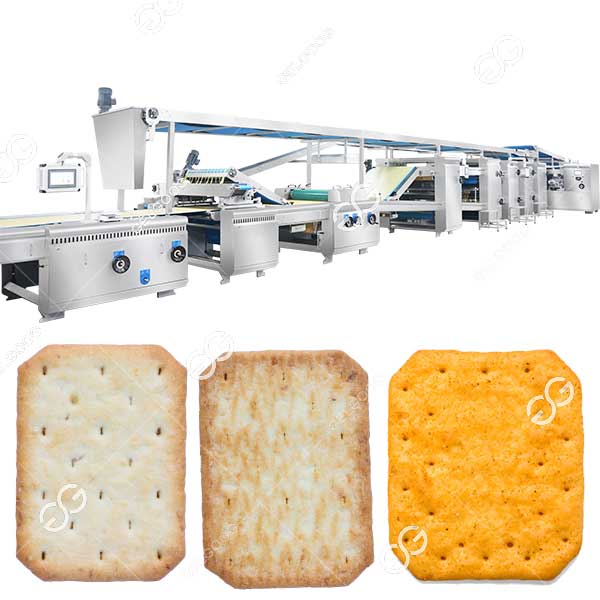

How it Works

Automatic sandwich cracker making machines operate by seamlessly integrating several key components:

- Dough preparation and sheeting: The machine mixes the ingredients to form a smooth dough, which is then pressed into uniform sheets.

- Cutting and baking: The dough sheets are cut into individual cracker shapes and baked to perfection in a tunnel oven.

- Filling and assembling: The baked cracker are filled with a precise amount of cream or other fillings and then sandwiched together.

- Packaging: The finished sandwich cracker are automatically packaged to ensure freshness and extend shelf life.

Key Features and Benefits

1. High production capacity

Automatic sandwich cracker making machines can produce thousands of sandwich cracker per hour, making them ideal for large-scale production. Models such as the GG-BG1200 can handle up to 1200 kg per hour, ensuring you can meet high market demands.

2. Consistent product quality

Automation ensures that each cracker is uniform in size, shape and thickness. The machine’s precise filling system ensures that each sandwich cracker has the perfect amount of filling, resulting in a consistent taste and appearance.

3. Labor savings

By automating the production process, the machine significantly reduces the need for labor. This not only reduces labor costs, but also minimizes the risk of human error, ensuring a more reliable production line.

4. Versatility

The machine can be adjusted to produce crackers of various shapes and sizes. It also supports different filling types, allowing you to create a diverse product that caters to a variety of consumer preferences.

5. Hygiene and safety

All parts that come into contact with food are made of food-grade materials, ensuring easy cleaning and disinfection. This design meets strict food safety standards and provides a hygienic production environment.

6. Energy efficiency

Modern sandwich cracker making machines are designed with energy efficiency in mind. They consume less electricity while maintaining optimal performance, helping you reduce operating costs and minimize environmental impact.

Conclusion

The automatic sandwich cracker making machine is a worthwhile investment for any bakery or snack manufacturer looking to increase productivity, improve product quality and remain competitive in the market. With its advanced features, high efficiency and flexibility, the machine has the potential to revolutionize the way sandwich cracker are made.

Leave A Message To Get A Quote

Reviews

There are no reviews yet.