The fully automatic biscuit sorting machine is a key automated piece of equipment connecting the biscuit cooling line and the final packaging machine. Through advanced vision recognition and mechanical guidance technology, it automatically organizes disordered biscuits into a neat, aligned arrangement and stably conveys them to the packaging machine. It is the core equipment for achieving full automation of the biscuit packaging production line and improving overall efficiency.

Equipment Overview: An Intelligent and Efficient Production Line Bridge

Our automatic biscuit sorting machine is designed for high-paced industrial production, ensuring stable and precise feeding before packaging.

Flexible Mechanical Guiding and Arranging Mechanism

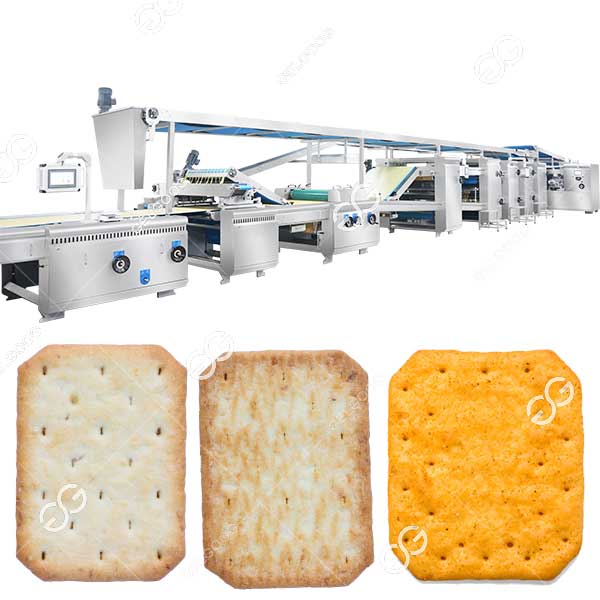

- Equipped with adjustable guide rails, forks, or conveyor belts, it can adapt to various biscuit shapes (such as round, square, and oval), gently aligning and turning the biscuits, greatly reducing biscuit loss.

Synchronous Conveying and Buffering System

- Synchronized with the upstream cooling line and downstream packaging machine, the built-in buffer design smoothly handles short-term speed fluctuations in the production line, ensuring continuous and stable feeding.

Industrial-Grade Control and Linkage

- PLC integrated control allows signal interaction with the packaging machine, achieving line-wide linkage. Touchscreen operation makes parameter setting simple and production changeover convenient. Hygiene and Safety Design: Key contact parts are made of food-grade materials. The open structure facilitates quick cleaning and maintenance, complying with food safety production standards.

Why Our Cookie Sorting Machine is Indispensable:

- Completely Eliminates Packaging Line Bottlenecks: Manual tray sorting is a major speed bottleneck in packaging lines. This machine achieves high-speed, uninterrupted automatic cookie sorting, fully releasing the efficiency of high-speed packaging machines, increasing overall packaging efficiency by up to 50%.

- Extremely High Stability and Low Cookie Breakage Rate: Precise mechanical design and gentle handling ensure an extremely low cookie breakage rate (e.g., <0.5%) even at high speeds, directly protecting your product profits.

- Powerful Shape Adaptability: Quickly adapts to different sizes and shapes of cookie products through simple module changes or parameter adjustments, meeting your production needs for frequent product changes.

- Precise ROI: One machine can replace 4-8 tray sorting workers, solving recruitment difficulties. Investment can typically be recovered within 6-12 months through saved labor costs.

Focus on Back-End Automation

Choosing GELGOOG means choosing an expert with in-depth knowledge of cookie production line processes.

- Integrated Production Line Thinking: We not only provide standalone machines, but also understand the key connections between cookie sorting machines and upstream/downstream equipment, enabling us to provide you with the optimal production line integration solution.

- Extensive Project Experience: We have provided successful automated cookie sorting solutions for numerous cookie brands and have experience handling various complex cookie shapes.

- Lifetime Technical Support: We provide full-cycle services from on-site planning, installation, commissioning to remote support, ensuring your equipment always operates efficiently.

Typical Applications: Cookie sorting before round/square/oval cookies enter the pillow packaging machine. Arranging and stacking wafers before entering the cartoning machine. Automatic feeding of fragile biscuits such as soda crackers.

Core Value for Your Business:

- Achieving Full Packaging Automation: Filling the automation gap between the cooling line and the packaging machine is a key step in creating a “lights-out factory.”

- Ensuring Product Quality: Reducing human contact and lowering the risk of contamination; simultaneously reducing cookie breakage caused by improper human operation.

- Improving Management Efficiency: Visualized production data and standardized processes greatly simplify production site management.

Is your cookie packaging line inefficient due to manual tray placement? Fully automatic cake sorting machines bridge the “last mile” of your production line automation journey.

Contact us now for a free production line assessment and solutions!

Reviews

There are no reviews yet.