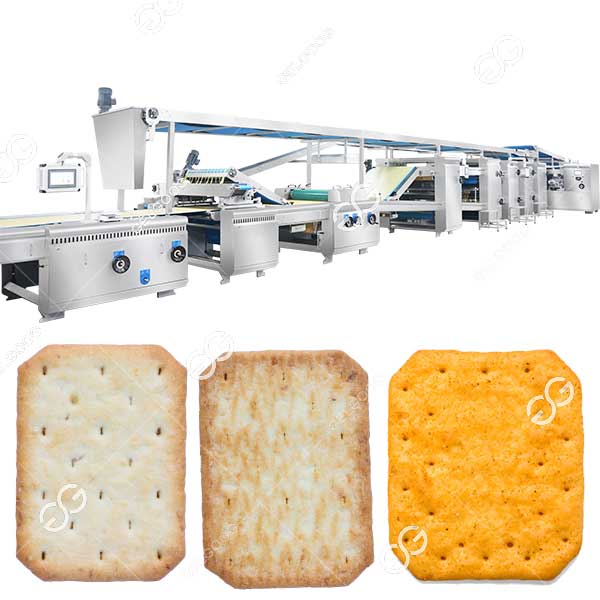

The automatic biscuit production line integrates multiple unit operations, including raw material mixing, dough forming, biscuit baking, cooling and packaging.

Realizing a fully automated production process from raw materials to finished biscuits, which can greatly release the productivity of the enterprise.

Biscuit Production Line Structure and Manufacturing Process

- Raw material mixing process: Equipped with a multi-dimensional stirring paddle design and an intelligent variable speed control system, the stirring paddle can be mixed from multiple angles and speeds in all directions, and flexibly adjusted according to different biscuit recipes to fully blend the raw materials and achieve the ideal mixing effect.

- Forming part: Equipped with a high-precision mold system, these molds are made through CNC processing technology with precise dimensions to ensure that the biscuits are regular in shape and clear in edges after forming. Meet the production needs of biscuits of various shapes, sizes and customized by customers in the market.

- Baking link: The automatic biscuit production line uses innovative baking technology that combines hot air circulation with far-infrared heating, and combines high-precision temperature sensors and partition temperature control systems to make the temperature in the oven evenly distributed and consistent in every corner.

- Packaging process: The use of high-speed automated packaging equipment not only has a fast packaging speed, but also has extremely high accuracy, and strictly controls the quantity, specifications and other requirements of each package of biscuits. It has strong adaptability to all kinds of packaging materials and can flexibly adjust the packaging form.

Reasons for Choosing Automatic Biscuit Production Line

- In terms of production efficiency: each link has a high degree of automation, such as efficient and uniform mixing, fast and accurate molding, precise control of baking, and high-speed and accurate packaging. The overall linkage greatly shortens the production cycle, allowing enterprises to produce more high-quality biscuit products.

- Easy to clean and maintain: The equipment design of the production line is easy to clean, with a smooth surface and no sanitary dead corners. Moreover, during the maintenance of the equipment, the entire production line can be disinfected and cleaned regularly to ensure compliance with food safety standards.

- Stable production rhythm: The biscuit production line is not affected by factors such as worker fatigue, ensuring that the production time interval of each biscuit is basically the same. This can effectively plan the production process and facilitate the company to arrange subsequent packaging, transportation and other links.

- Efficient use of raw materials: The automated batching system precisely dispenses raw materials as per the specified formula, thereby minimizing waste. Concurrently, the meticulous regulation of the manufacturing process allows for a more judicious use of materials, enhancing their utilization rate and consequently lowering production expenses.

Biscuit Production Line For Sale

As a professional biscuit machine manufacturer, we offer small, medium, and large biscuit production lines.

Furthermore, our automatic biscuit machines can produce a variety of biscuit types, such as cream biscuits, sandwich biscuits, soda crackers, and vegetable biscuits.

Our machines offer a variety of heating methods (electric, gas, and oil).

Our current product models include:

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions | Voltage |

| (without packing machine) | |||||

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Biscuit Production Line Manufacturers

As a leading manufacturer of biscuit production lines, we specialize in designing, manufacturing, and installing customized automated solutions tailored to diverse production needs.

Our expertise ensures reliable performance, compliance with international food safety standards, and continuous innovation in biscuit-making technology.

With comprehensive after-sales support and technical services, we partner with clients worldwide to enhance their production capabilities and maximize operational efficiency.

Reviews

There are no reviews yet.